Coated Aluminum Coil

- Brand Name:ALUMETAL

- Temper:O~H112

- Tolerance:±1%

- Certificate:CE/SGS/ISO9001

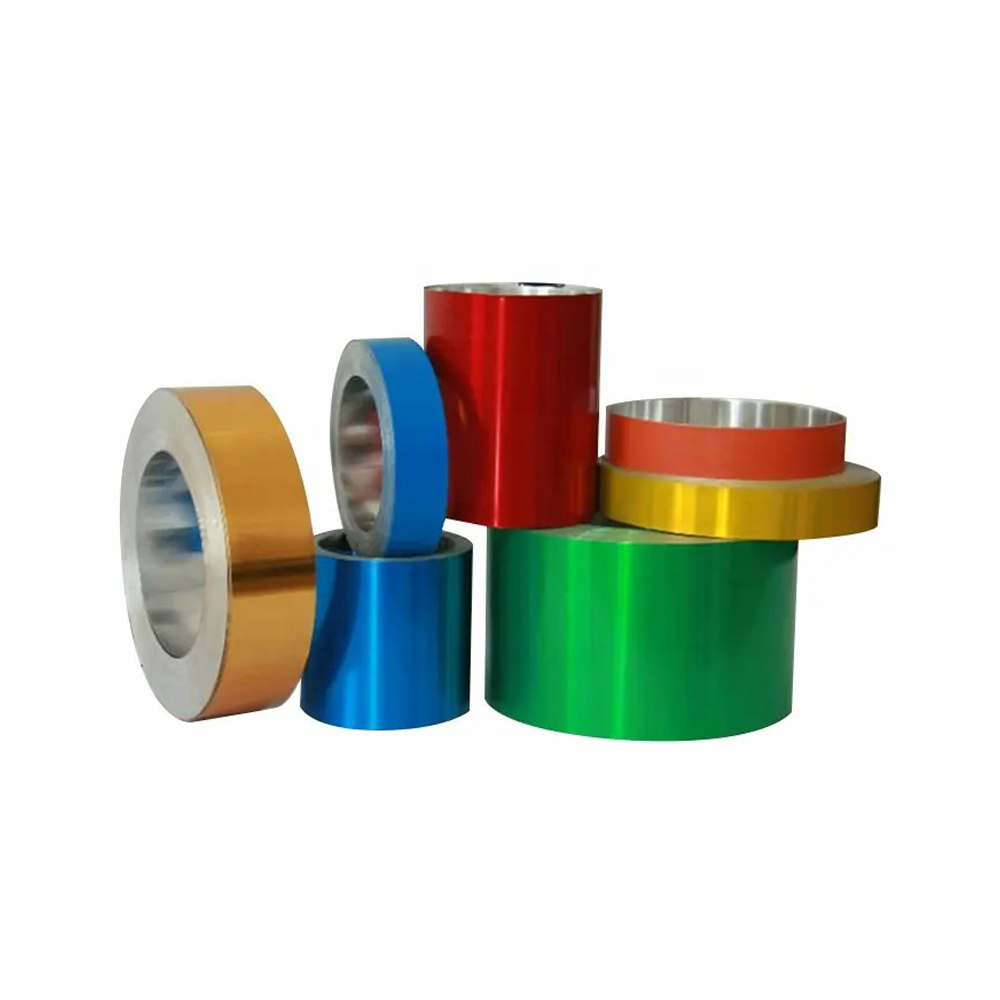

- Color:Customer’s Requirements Or Standard, Etc

- Minimum Order Quantity:500 Square Meters

- Surface Treatment:Anodized, Brushed, Mirror, PE Coated, Printing, PVDF Coated, FEVE

Product Description

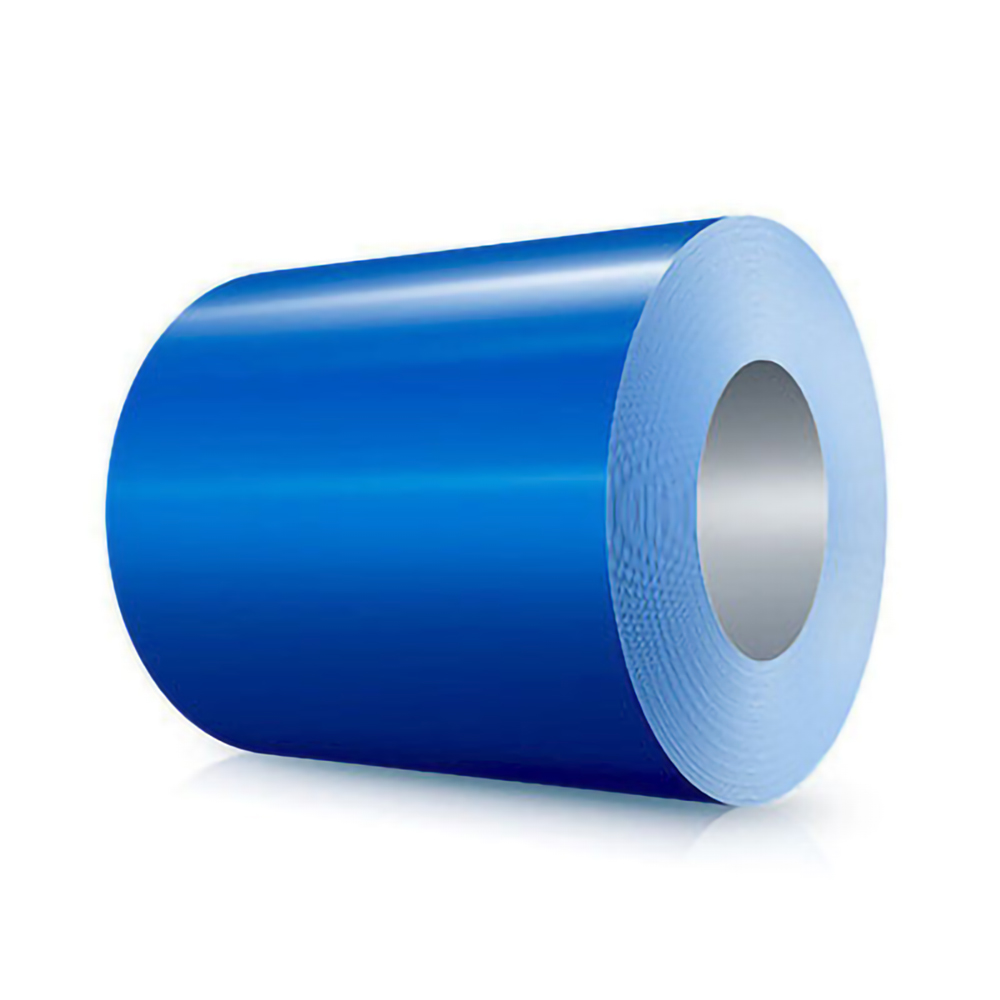

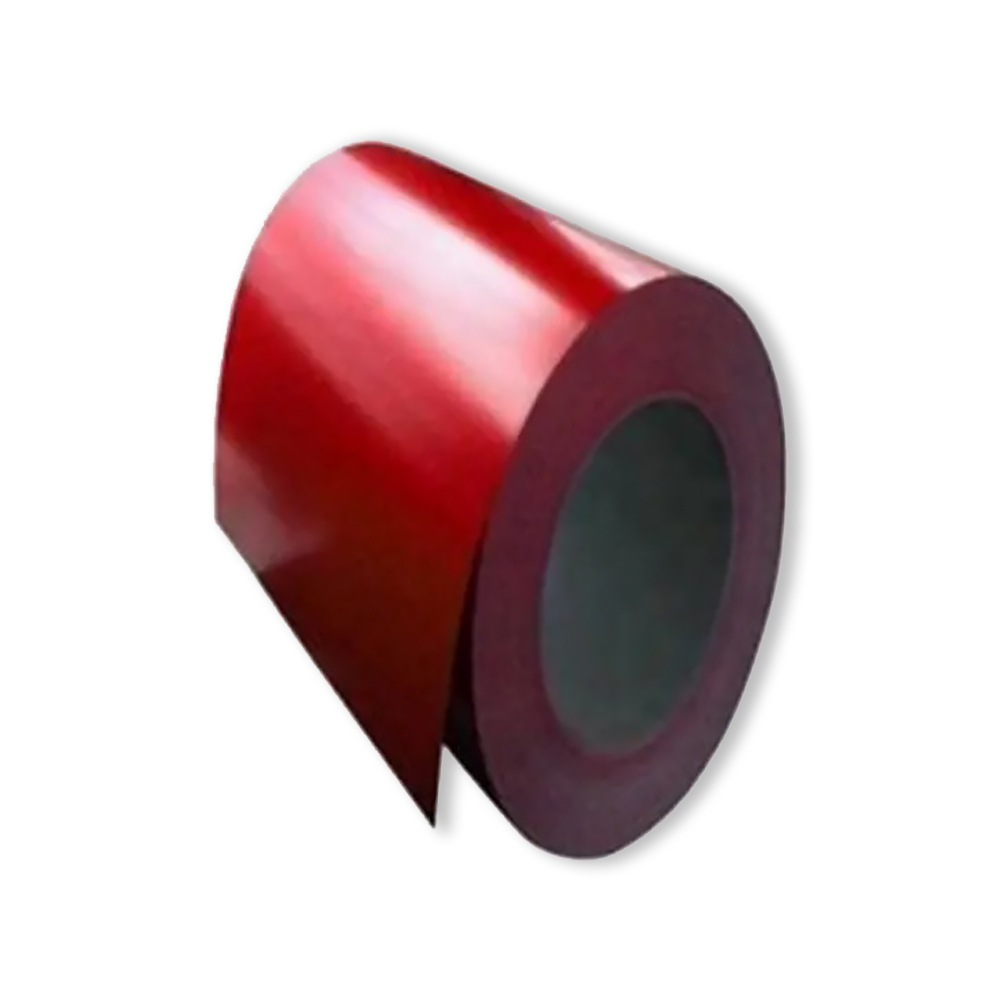

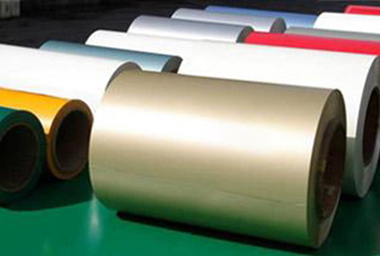

Coated Aluminum Coil

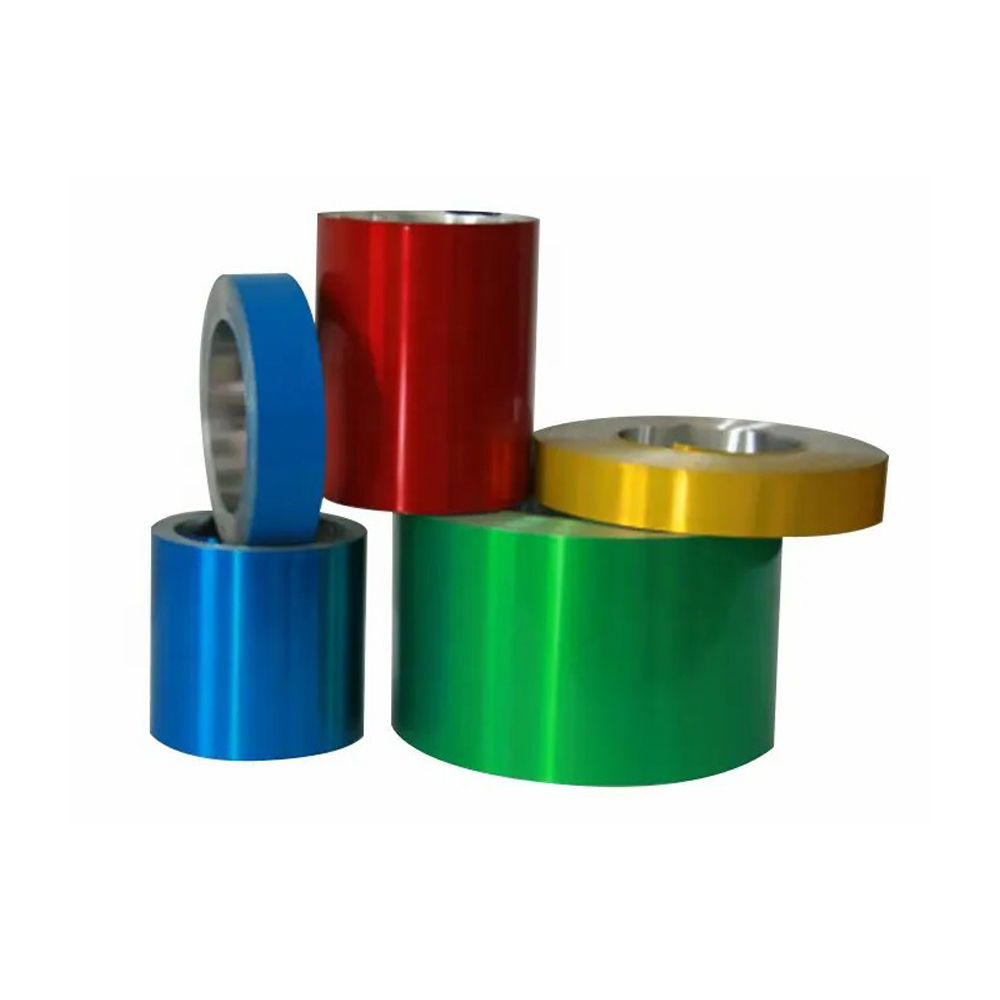

Color coated aluminum coil, processed through roller coating and bakinowith precise polyester, PVDF paints. With variety of colors you canchoose easilv. Chromatic aberration is small.impact resistance is stronand easy to be processed, and all its performance has reached or surpassethe national criteria. We equipped with 3 sets of the most advancedautomated coating lines, Thickness ranging from 0.03mm to 0.6mm andwidth ranging from 800mm to 2020mm,provide customers with endlesspossibilities.

High quality coated aluminum products are widely used inindoor and outdoor decoration, aluminum composite panels (ACP), roofinccurtain walls, ceiling, rain gutters, rolling shutters, chimney covers, sodacans, windows and doors.

| Alloy | Thickness | Width | Temper |

| A1050, A1060, A1070, A1100 | 0.2MM~200MM | 10MM~2500MM | O, H12, H22, H14, H16, H18, H24, H26, etc |

| A3003, A3105, A3004 | 0.2MM~200MM | 10MM~2500MM | O, H14, H18, H24, etc |

| A5052, A5005, A5083, A5754 | 0.2MM~200MM | 10MM~2500MM | O, H14, H18, H24, etc |

| A6061, A6082, A6063 | 0.2MM~200MM | 10MM~2500MM | T4, T6, T651, etc |

| A8011 | 0.2MM~200MM | 10MM~2500MM | O, H12, H22, H14, H16, H18, H24, H26, etc |

Application

To produce aluminum composite panel or aluminum veneersUsed in exterior applications for decoration and protectionof exterior wall, canopy, roof and pillar, etc.Coated aluminum coil is also ideal for interior decoration forwall, ceiling, bathroom and kitchen, etcUsed in advertising boards or shop front decoration.

As a one ofthe foremost coated aluminum coil manufacturersand suppliers in China, all coated coils are painted by our owrcoating production line. We can produce different aluminuncoil coming with different types of coating,including, PVDcoated, polyester coated, brushed and chromate cleaning coils

| Production Process | Cold Rolled, Hot Rolled |

| Internal Diameter | 150mm, 305mm, 405mm, 505mm or per request |

| Coil Weight | 2-4 tons |

| Standard | ASTM-B209, EN573-1, GB/T3880.1-2006 |

| Color | Alumetal color and customized color as sample, Ral or Pantone |

| Color Standard | E<2 or it is not obvious by eyeballing |

| Coating | PE, PVDF, Epoxy |

| Coating Thickness | PVDF>=25 micron POLYESTER>=18 micron |

| Coating Adhesive | Not lower than first grade impact: no any crack (50kg/cm, ASTM D-2794:1993) |

| MOQ | 5~8 Tons (According to specification) |

| Delivery Time | Future goods: 20~30 work days, ready stock: 7-10 days. |

| Quality of Material | Totally free from detects like white rust, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set. |

| Pencil Hardness | >2HB |

| Bend Strength | >100 times |

| Boiling Point | No any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

| Corrosive | Surface deep in the 5% muriatic acid and 5% NaCl, interior deep in the 2% muriatic acid and 2% NaCl, after 48 hours, no change |

| Package | Export wooden pallets, craft paper. The bundle weight not exceed 2 MT, Loading: by 1x20GP |

Color

Our Certificate

Packaging & Shipment

Packaging:

1) LCL by wooden pallet package ,fumigation wooden pallet is available2)FCL by wooden pallet package loaded in the container

3)FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity).

lmportant shipping particular will be sent to you by E-mail after delivery of the goods.

Sample Availability & Policy:

Sample courier freight will be paid by buyer

which can be refunded after order placed ,or send freely

Product Characteristics

FAQ

A1:1. MOQ (Minimum Order Quantity): 500m² but it can be less if we have stocks

2. Delivery Time: within 15 days after receiving deposit

3. Payment: 30% TT in advance ,70% against BL of copy or LC

A2:Yes, stable good quality is key for long time business cooepration.

Factory have passed ISO9001:CE SGS, etc .

A3: Yes, OEM accept. Just need to give us yours logo, we will send some protective film design for your choose

A4: 1. Width: 1000-1575mm; 1220mm, 1250mm, 1500mm are recommended.

2. Length: accept custom length, recommend 2440mm, 3050mm, 4050mm, 5000mm

3. Panel Thickness:2mm-6mm; recommend 3,4mm

4.Aluminum thickness:0.05-0.5mm

A5: Yes, samples are available if you are interested in our products.