Brush aluminum composite panel

- Brand Name:ALUMETAL

- Minimum Order Quantity:500 Square Meters

- Certificate:SGS, CE, ISO 9001

- Warranty: 15 Years

- Material:Non-toxic,non-pollution

- Application: Residential, Commercial

- Function:Anti-Static, Antibacterial, Fireproof, Mould-Proof

- Surface Treatment:Anodized, Brushed, Mirror, PE Coated, Printing, PVDF Coated, FEVE

Product Description

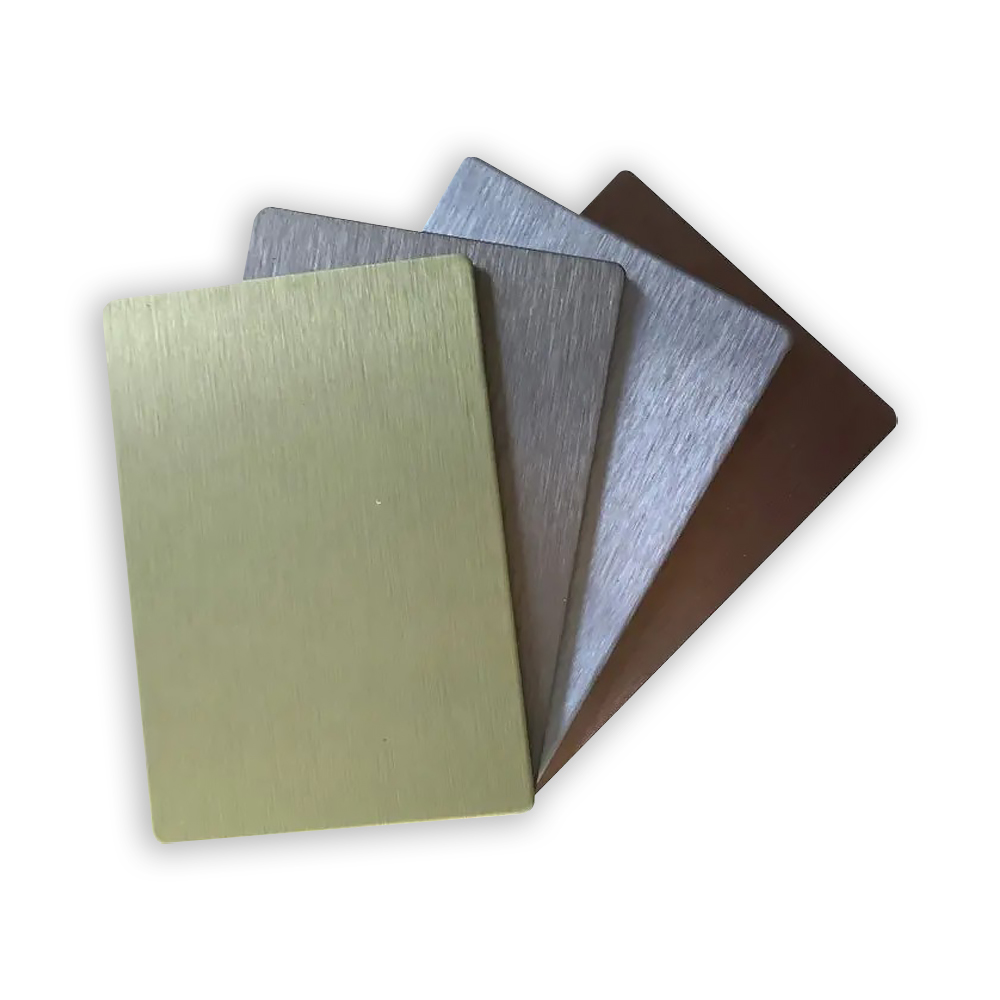

Brush aluminum composite panel

Brushed aluminum composite panel is a type of building material that is widely used in modern architecture and interior design. It consists of two aluminum sheets bonded to a non-aluminum core, such as polyethylene, which provides structural stability and insulation.

The surface of the aluminum sheets is treated with a special brushing technique that creates a textured and metallic appearance. This brushed finish can range from a coarse texture to a more subtle grain, depending on the desired aesthetic.

| Specifications Of Aluminum Composite Panel | |

| Normal Width | 1220mm, 1250mm, specially 1500mm custom accepted |

| Panel Length | 2440mm ,5000mm,5800mm ,normally within 5800mm. |

| for 20ft container custom accepted | |

| Panel Thickness | 2mm 3mm 4mm 5mm 6mm 8mm … |

| Aluminum Alloy | AA1100,AA3003,AA5005 …(Other Grade On Requirement) |

| Aluminum Thickness | 0.05mm to 0.50mm |

| Coating | PE coating , PVDF coating, NANO, Brush surface, mirror surface |

| PE Core | Recycle PE Core/Fireproof PE Core/Unbreakable PE Core |

| Color | Metal/Matt/Glossy/Nacreous/Nano/Brushed/Mirror/Granite/Wooden |

| Core Material | HDP LDP Fire-proof |

| Delivery | Within two weeks after receiving deposit |

| MOQ | 500 Sqm per color |

| Brand/OEM | Alumetal/Customized |

| Payment Terms | T/T, L/C at sight, D/P at sight,Western Union |

| Packing | FCL:In bulk;LCL:In Wooden pallet Package;according customers’ requirement |

Application

Brushed aluminum composite panels are popular for their durability, lightweight construction, and versatility.

They can be used for a wide range of applications, including Constructional exterior curtain walls, Decorative renovation for storey-added old buildings, Indoors decoration for interior walls, ceilings, bathrooms, kitchens and balconies, Advertisement board, display platforms and signboards, Wallboard and ceilings for tunnels, Raw materials in industrial purpose, Materials used for vehicle and boat.

They are also easy to install and maintain, making them a popular choice for both commercial and residential projects.

Brush aluminum composite panel advantages

- – Excellent fire resistance, hardly flammable.

- – Excellent sound, heat insulation

- – Superior impact and peel strength

- – Excellent surface flatness and smoothness

- – Light weight and easy for maintenance

Color

| Metal Colors Series |

Check Alumetal color chart |

| Matt Colors Series | |

| Glossy Series | |

| Brushed Series | |

| Granite Series | |

| Wooden Series | |

| Nano /Nacreous Series | |

| Customized color can be matched as sample or Ral and Pantone color code | |

Our Certificate

The whole production process from raw material to finished product is under a strict quality control. All the products comply with UL, RoHs, REACH,SGS International standards.Our UL No: E252099. You rest assured of our good quality.

Packaging & Shipment

Packaging:

1) LCL by wooden pallet package ,fumigation wooden pallet is available2)FCL by wooden pallet package loaded in the container

3)FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity).

lmportant shipping particular will be sent to you by E-mail after delivery of the goods.

Sample Availability & Policy:

Sample courier freight will be paid by buyer

which can be refunded after order placed ,or send freely

Product Characteristics

FAQ

A1:1. MOQ (Minimum Order Quantity): 500m² but it can be less if we have stocks

2. Delivery Time: within 15 days after receiving deposit

3. Payment: 30% TT in advance ,70% against BL of copy or LC

A2:Yes, stable good quality is key for long time business cooepration.

Factory have passed ISO9001:CE SGS, etc .

A3: Yes, OEM accept. Just need to give us yours logo, we will send some protective film design for your choose

A4: 1. Width: 1000-1575mm; 1220mm, 1250mm, 1500mm are recommended.

2. Length: accept custom length, recommend 2440mm, 3050mm, 4050mm, 5000mm

3. Panel Thickness:2mm-6mm; recommend 3,4mm

4.Aluminum thickness:0.05-0.5mm

A5: Yes, samples are available if you are interested in our products.