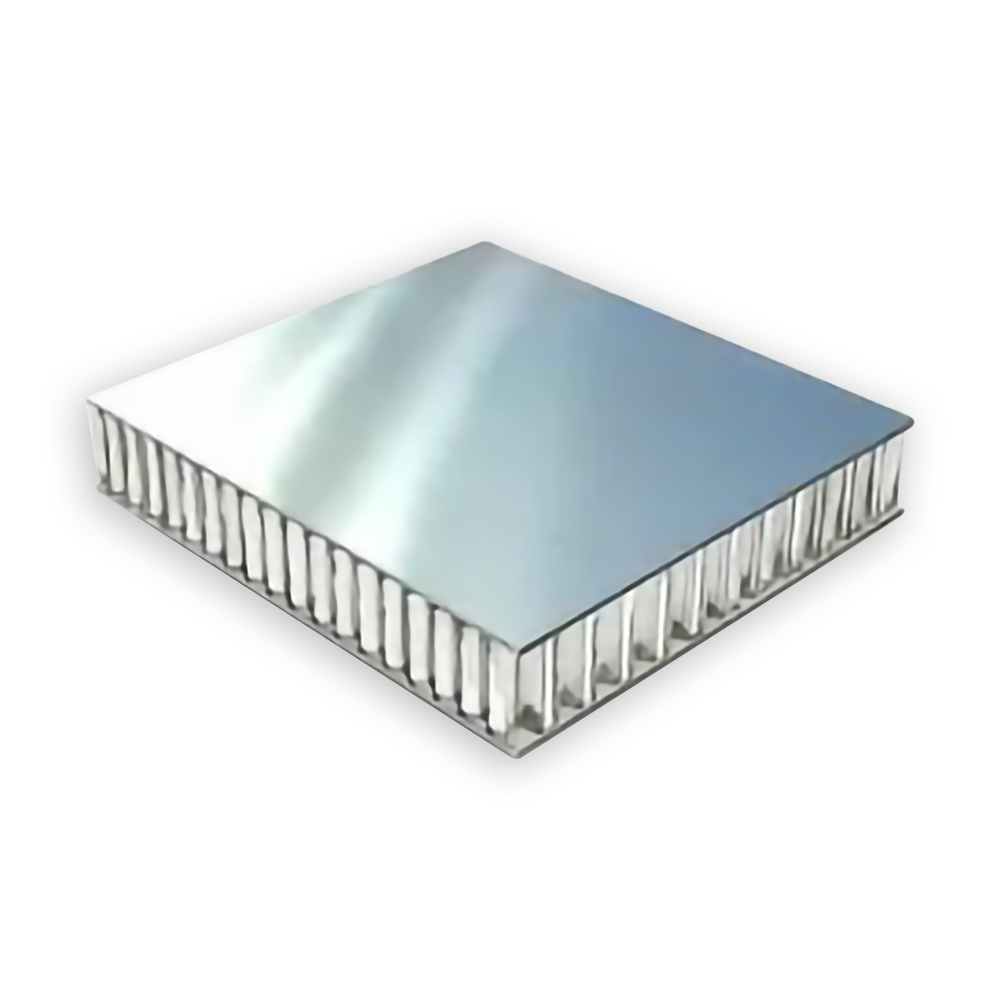

Aluminum Honeycomb Panel

- Brand Name:ALUMETAL

- Place of Origin:Shanghai, China

- Panel Thickness:4-500mm

- Core Foil Thickness:0.04mm – 0.10mm

- Fire Resistance:A2 Grade

- Certificate:CE/S G S/ISO9001

- Flatwise Compression:1MPa – 20MPa

- Coating:PE PVDF FEVE ANODIZED & Mill Finish

- Application:Outdoor

- Surface Treatment:Anodized, Brushed, Mirror, PE Coated, Printing, PVDF Coated, FEVE

Product Description

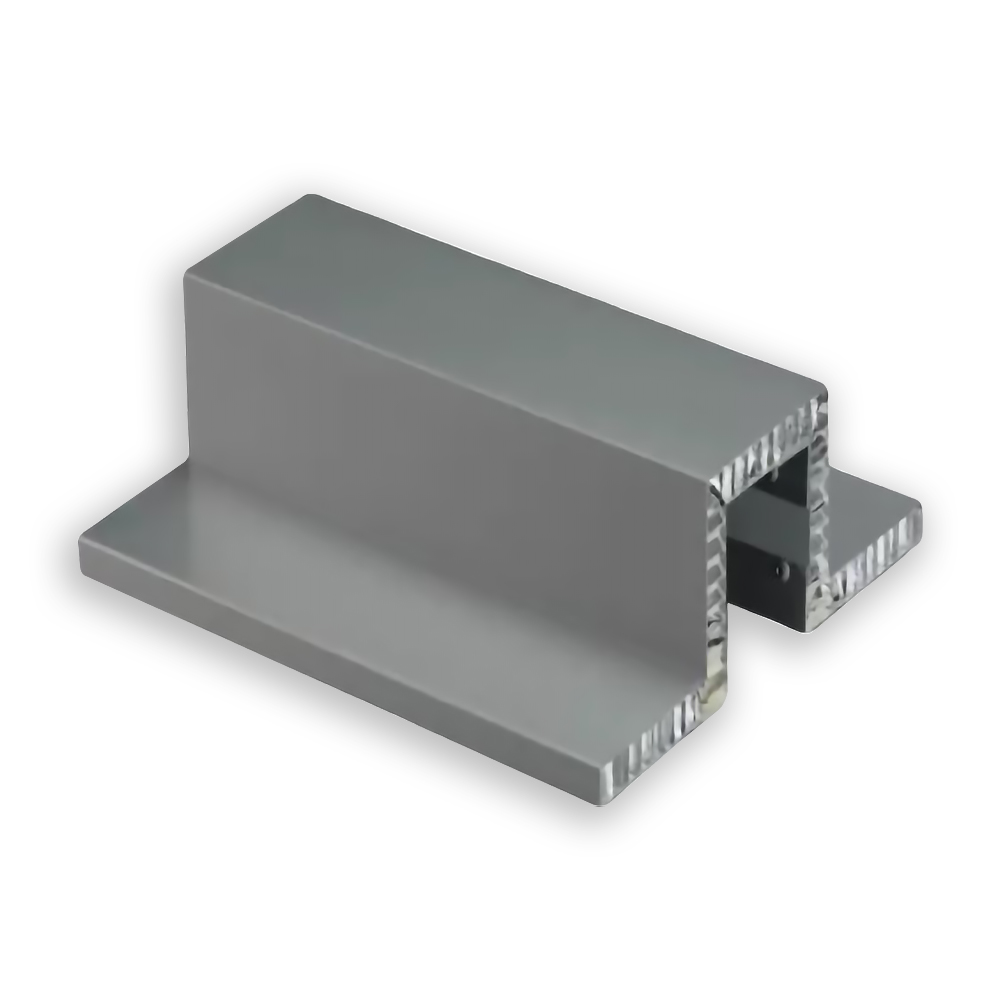

Aluminum Honeycomb Panel

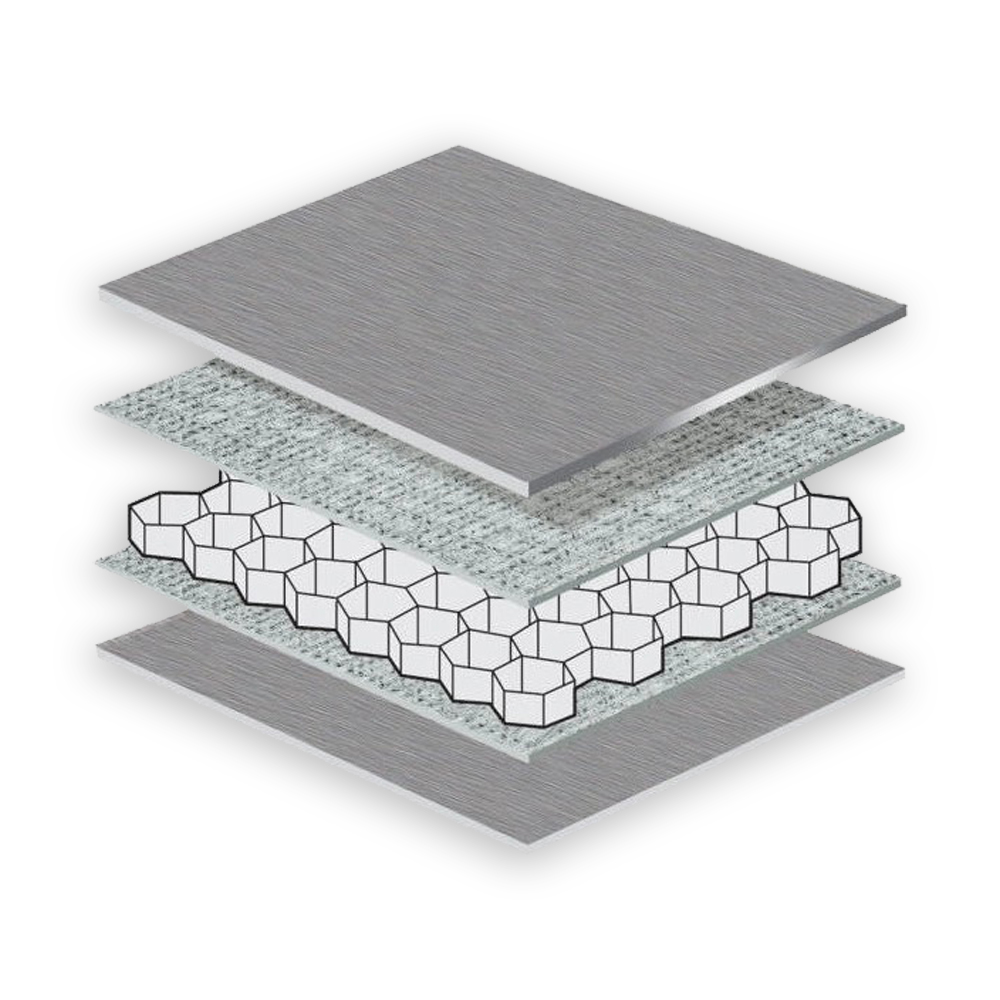

Aluminum honeycomb panel, also known as aluminum honeycomb composite panel, is a lightweight and high-strength building material made of two aluminum sheets and a honeycomb core made of aluminum or other materials. The aluminum sheets are bonded to the honeycomb core using high-strength adhesive.

Aluminum honeycomb panel has become increasingly popular in the construction industry due to its excellent properties, such as lightweight, high strength, good corrosion resistance, good sound insulation and thermal insulation performance, easy installation, and attractive appearance. It can be used in a variety of applications, such as exterior and interior wall cladding, ceiling, roofing, partition, door, and furniture.

| Aluminum Alloy | AA3003 H18, AA5052 H18 |

| Total Panel thickness | 4mm, 8mm, 10mm, 15mm, 25mm, Max 500mm |

| Aluminum Skin thickness | 0.5mm, 0.8mm, 1mm, 1.5mm, Max 3mm |

| Coating: | PVDF, PE, Anodized, Mill Finished, Embossed, Granite etc |

| Length: | 2440mm, 3000mm, 3500mm, 5800mm, Max 10000mm |

| Width: | 1000mm, 1220mm, 1250mm, 1500mm, Max 2200mm |

| Honeycomb Core Foil Thickness: | 0.02mm, 0.04mm, 0.05mm, 0.06mm, 0.08mm Max 0.1mm |

| Honeycomb Core Cell Size: | Micro-Aperture Honeycomb:1/10”(2.6mm), 1/8”(3.17mm), 1/6”(3.47mm), 1/5”(5.2mm), Regular Honeycomb: 1/4”(6.35mm), 1/3”(8.47mm), 3/8 ”(9.53mm), 1/2”(12.7mm), 3/4”(19.05mm), 4/5”(20.32mm), 1”(25.9m) |

| Honeycomb Core Cell Side Length: | Micro-Aperture Honeycomb:1.5mm, 1.83mm, 2mm,2.5mm, 3mm, Regular Honeycomb: 4mm, 5mm, 6mm, 7.5mm, 10mm, 12mm, 15mm |

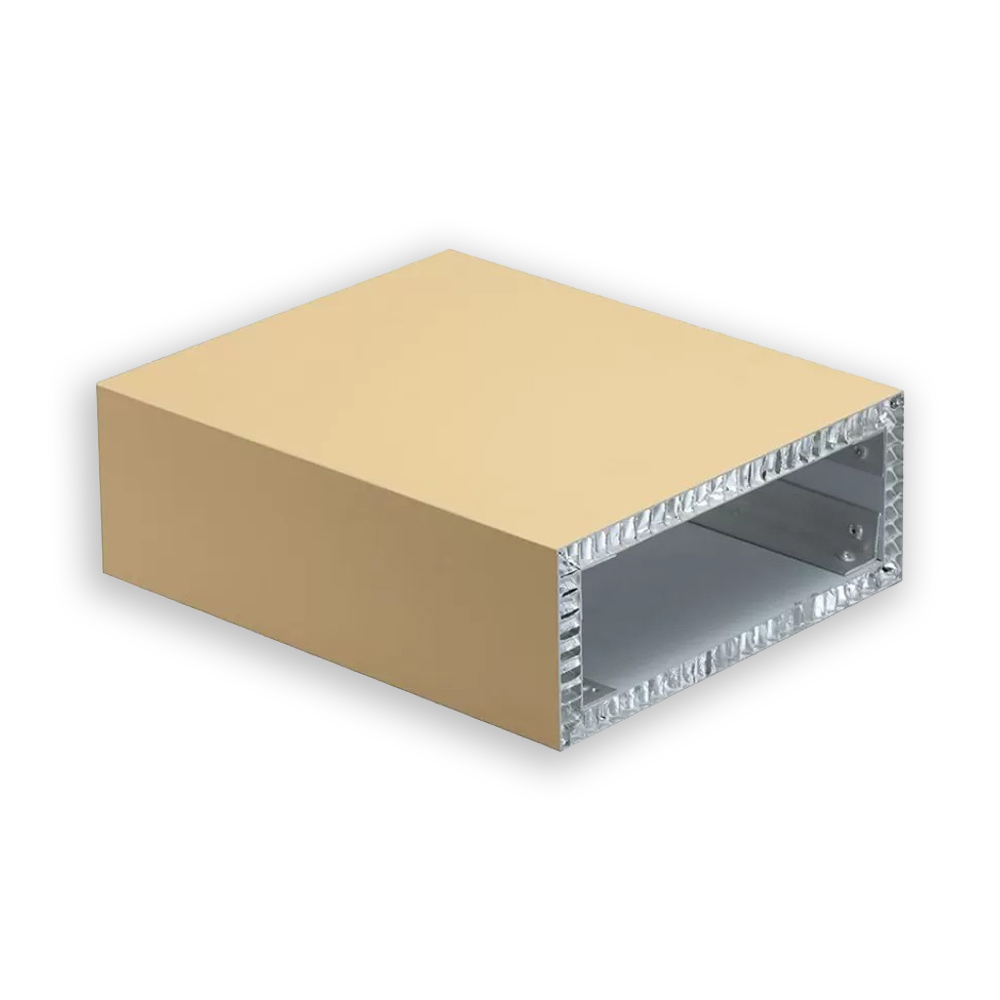

| Edge: | Close Edge, Open Edge |

Video

Application

- – Building exterior, interior wall covering, ceilings, partitions

- – Column covers and soffit and fascia panels

- – Signage and white boards

- – Canopy fascias and soffits

- – Doors

- – Furniture and Tables

- Application:Building&Construction,Solar,Ground Transportation,Marine,Furniture,Industry

Alumetal Aluminum Honeycomb Panel advantages

The honeycomb core structure of the aluminum honeycomb panel provides a high strength-to-weight ratio, making it ideal for use in applications where weight reduction is critical. The panel also has good thermal and acoustic insulation properties due to the air space within the honeycomb core. The aluminum surface of the panel can be treated with various coatings and finishes to enhance its appearance and improve its durability.

Aluminum honeycomb panel is a sustainable building material as it is recyclable and has a long service life, reducing the need for frequent replacement. It is also fire-resistant and can withstand extreme weather conditions, making it suitable for use in areas with high fire risk or harsh weather.

Color

| Metal Colors Series |

Check Alumetal color chart |

| Matt Colors Series | |

| Glossy Series | |

| Brushed Series | |

| Granite Series | |

| Wooden Series | |

| Nano /Nacreous Series | |

| Customized color can be matched as sample or Ral and Pantone color code | |

Our Certificate

Packaging & Shipment

Packaging:

1) LCL by wooden pallet package ,fumigation wooden pallet is available

2)FCL by wooden pallet package loaded in the container

3)FCL in bulk loaded in the container

4) Customized package according to your demands

Shipping:

7-15 days after receipt of payment(depend on order quantity).

lmportant shipping particular will be sent to you by E-mail after delivery of the goods.

Sample Availability & Policy:

Sample courier freight will be paid by buyer

which can be refunded after order placed ,or send freely

Product Characteristics

FAQ

A1:1. MOQ (Minimum Order Quantity): 500m² but it can be less if we have stocks

2. Delivery Time: within 15 days after receiving deposit

3. Payment: 30% TT in advance ,70% against BL of copy or LC

A2:Yes, stable good quality is key for long time business cooepration.

Factory have passed ISO9001:CE SGS, etc .

A3: Yes, OEM accept. Just need to give us yours logo, we will send some protective film design for your choose

A4: 1. Width: 1000-1575mm; 1220mm, 1250mm, 1500mm are recommended.

2. Length: accept custom length, recommend 2440mm, 3050mm, 4050mm, 5000mm

3. Panel Thickness:2mm-6mm; recommend 3,4mm

4.Aluminum thickness:0.05-0.5mm

A5: Yes, samples are available if you are interested in our products.