What is an ACP Sheet? A Complete Guide to Aluminum Composite Panels

In the world of modern architecture and construction, ACP Sheet—also known as Aluminum Composite Panel—has become a widely used and highly preferred material. Whether you’re designing a skyscraper façade, building signage, or interior decoration, ACP Sheets offer a unique combination of durability, aesthetic appeal, and cost-effectiveness.

This article provides a detailed look into what ACP Sheets are, their structure, benefits, applications, and why they are the ideal choice for your next construction or design project.

What is an ACP Sheet?

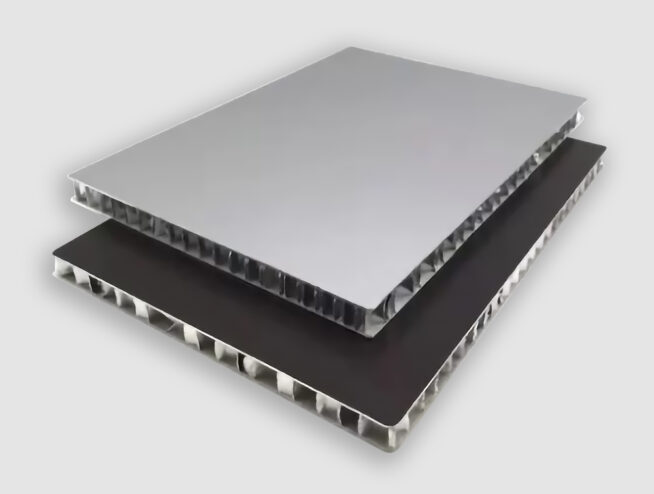

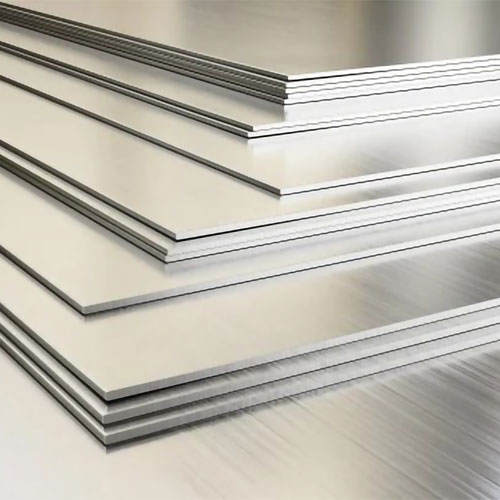

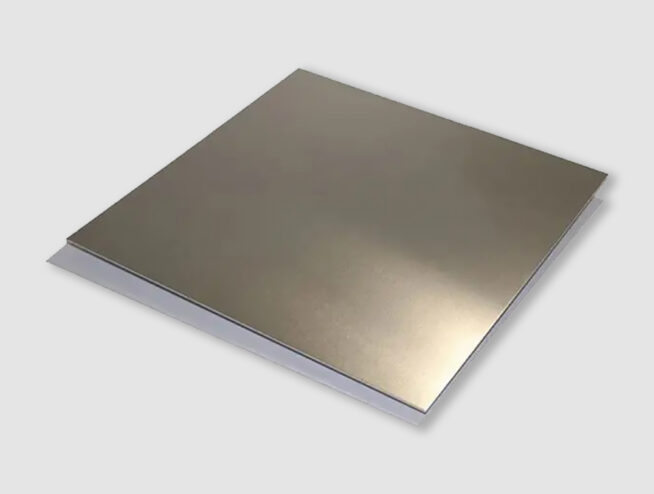

ACP stands for Aluminum Composite Panel, and an ACP Sheet typically consists of two thin layers of aluminum bonded to a non-aluminum core. The core is usually made of polyethylene (PE) or fire-retardant (FR) material, offering excellent rigidity while keeping the panel lightweight.

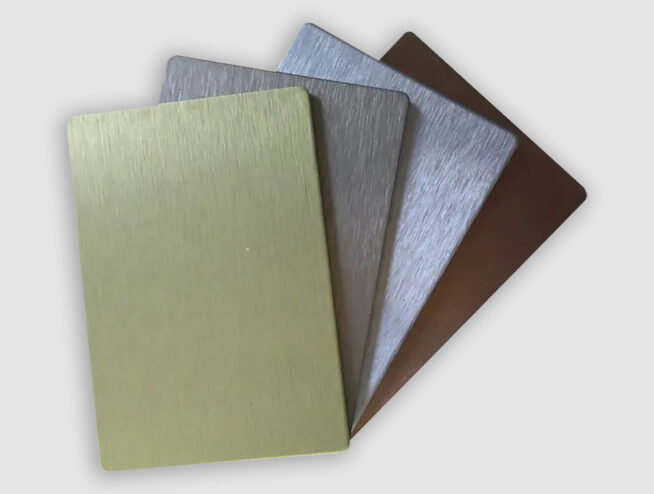

This combination creates a material that is not only strong and lightweight but also flexible enough to be cut, shaped, and installed with ease. The surface of the sheet is often coated with PVDF or polyester paint, which ensures long-term color retention and weather resistance.

Key Features of ACP Sheets

ACP Sheets are renowned for their numerous advantages, making them one of the most sought-after materials in construction and advertising industries. Some of the key features include:

-

Lightweight & Strong: The aluminum layers provide strength, while the core keeps the overall weight low, making it easier to handle and install.

-

Weather & UV Resistance: The surface coating protects the sheet from sunlight, rain, and temperature changes.

-

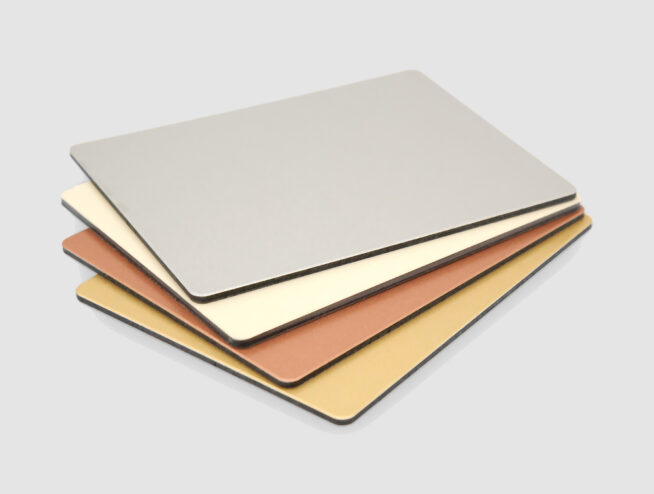

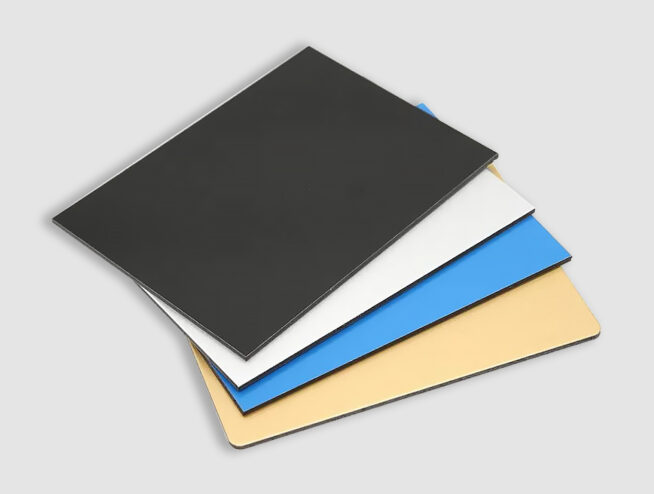

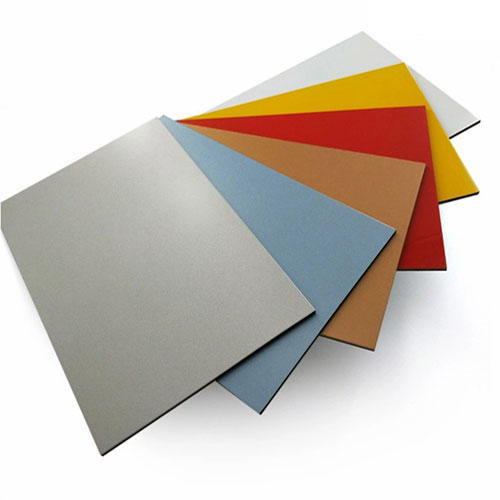

Aesthetic Variety: Available in a wide range of colors, finishes (matte, gloss, metallic), and textures (wooden, marble), ACP Sheets offer excellent design flexibility.

-

Fire Resistance: FR-grade ACP Sheets meet fire safety standards, especially important for public buildings and commercial spaces.

-

Low Maintenance: Easy to clean and highly durable, reducing maintenance costs over time.

-

Eco-Friendly: Many manufacturers offer recyclable and environmentally safe options.

Applications of ACP Sheets

The versatility of ACP Sheets makes them suitable for a wide range of applications, both exterior and interior. Here are some of the most common uses:

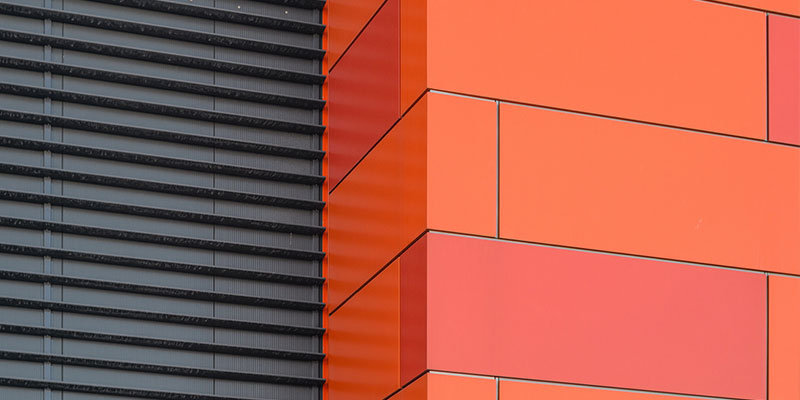

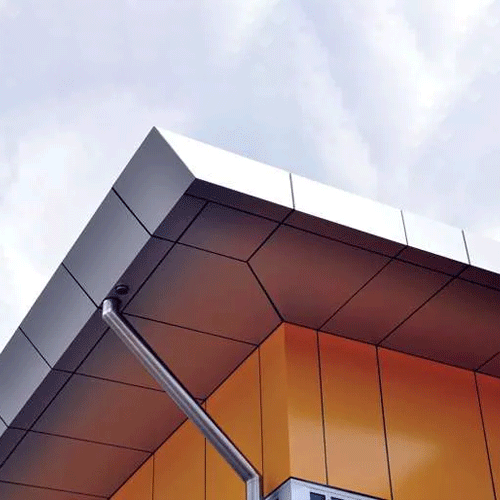

1. Building Façades & Cladding

ACP Sheets are widely used for external cladding in both commercial and residential buildings. Their sleek appearance and durability help improve the overall aesthetic and protect the building structure from weather damage.

2. Signage & Advertising Boards

Lightweight and easy to print on, ACP Sheets are the top choice for outdoor signage, hoardings, and advertising boards. They can be cut into any shape and offer vibrant color quality.

3. Interior Decoration

In modern interiors, ACP Sheets are used for false ceilings, wall partitions, column covers, and decorative panels. Their wide range of colors and textures allows architects to bring their designs to life.

4. Transportation and Industrial Use

Beyond architecture, ACP Sheets are also used in bus bodies, train panels, and other transportation sectors due to their strength-to-weight ratio and resistance to corrosion.

Why Choose ACP Sheets for Your Project?

If you are looking for a material that combines aesthetics, performance, and value, ACP Sheets are the answer. Here’s why they stand out:

-

Customization: Tailored sizes, colors, and finishes are easily available.

-

Cost-Effective: Compared to traditional materials like stone or solid aluminum, ACP Sheets offer significant cost savings.

-

Ease of Installation: Prefabricated panels reduce installation time and labor costs.

-

Long Lifespan: With proper installation and minimal maintenance, ACP Sheets can last over 15-20 years.

How to Select the Right ACP Sheet

Choosing the right ACP Sheet depends on your specific needs. Consider the following when selecting:

-

Core Material: Choose FR core for fire-sensitive areas.

-

Thickness: Standard thickness ranges from 3mm to 6mm.

-

Coating Type: PVDF for exterior use, polyester for interiors.

-

Brand Reputation: Always choose ACP Sheets from certified and well-reviewed manufacturers for consistent quality.

Conclusion

ACP Sheets have revolutionized the way architects and designers approach building facades and interior spaces. Their superior strength, wide design possibilities, and affordability make them a top choice in today’s construction industry.

Whether you are designing a commercial complex or revamping your store’s interior, ACP Sheet is a material you can trust for its quality, performance, and elegance.