Aluminium Composite Material (ACM)

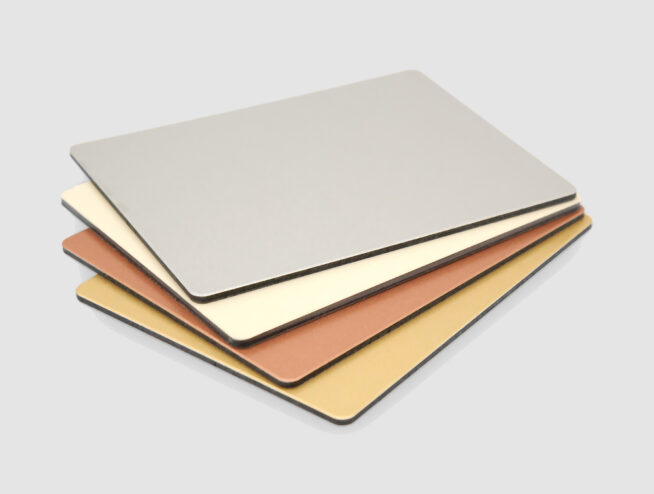

Aluminium Composite Material (ACM) is a modern, versatile construction material commonly used in building facades, interior and exterior cladding, signage, and various industrial applications. ACM panels consist of two thin layers of aluminium enclosing a non-aluminium core, which is typically made from polyethylene or a mineral-filled core.

ACM Composition and Structure

The typical structure of ACM panels includes:

- 1.Aluminium Layers: The outer layers are made of aluminium sheets, usually coated with protective paints or coatings that enhance durability and aesthetics.

- 2.Core Material: The core, sandwiched between the aluminium layers, can be made from different materials. Polyethylene (PE) cores are lightweight and flexible, while fire-retardant (FR) cores, often mineral-filled, offer enhanced safety features.

Advantages of ACM

- 1.Durability: ACM panels are highly resistant to weathering, corrosion, and impact, making them ideal for exterior applications.

- 2.Lightweight: Despite their strength, ACM panels are lightweight, reducing structural load and easing transportation and installation.

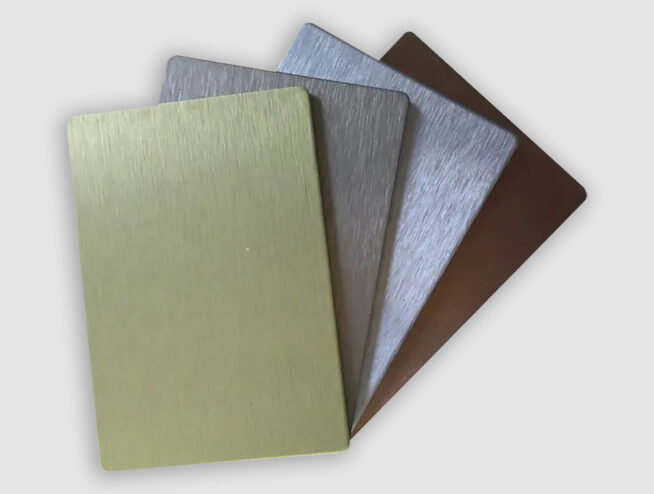

- 3.Aesthetic Versatility: Available in various colors, finishes, and textures, ACM allows architects and designers to achieve a wide range of aesthetic effects.

- 4.Thermal Efficiency: ACM panels provide excellent thermal insulation, contributing to energy efficiency in buildings.

- 5.Ease of Maintenance: The smooth surface of ACM panels is easy to clean and maintain, ensuring long-term appearance retention.

Aluminium Composite Material Applications

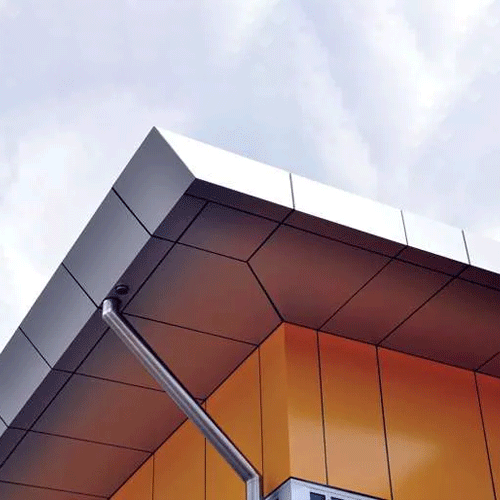

- 1.Architectural Cladding: ACM is widely used in both residential and commercial buildings for facades, curtain walls, and roofs. Its ability to create sleek, modern designs has made it popular in contemporary architecture.

- 2.Signage: Due to its smooth surface and ease of fabrication, ACM is a preferred material for signs, displays, and advertising boards.

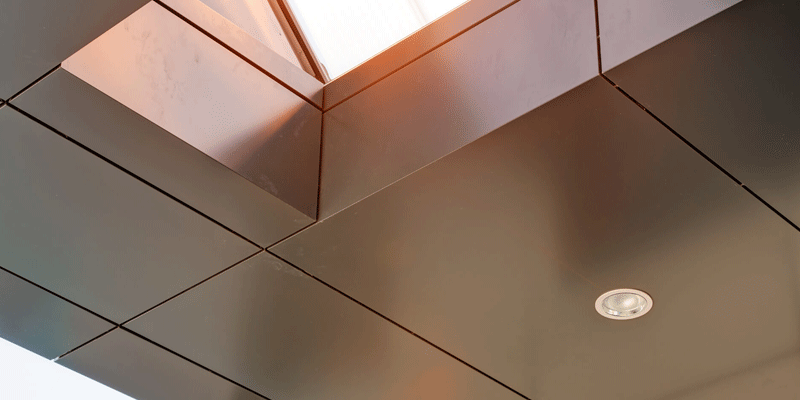

- 3.Interior Design: ACM is also used in interior applications such as partitions, false ceilings, and decorative features, providing a sophisticated and modern look.

- 4.Industrial Uses: Beyond construction and design, ACM finds applications in various industries, including transportation and electronics, where lightweight and durable materials are required.

Environmental Considerations

Fire Safety

The fire safety of ACM has been a topic of significant discussion, especially in light of high-profile building fires. Modern ACM panels with fire-retardant cores (FR cores) offer improved fire resistance compared to standard polyethylene cores. Compliance with stringent fire safety regulations and standards is crucial for ensuring the safe use of ACM in construction.

Installation and Fabrication

The installation of ACM panels requires specialized techniques and tools. Panels are often attached to a subframe, which is mounted to the building structure. Precision in cutting, bending, and shaping ACM panels allows for seamless integration into complex designs. Professional installation ensures structural integrity and aesthetic quality.

Conclusion

Aluminium Composite Material (ACM) represents a blend of strength, versatility, and aesthetic appeal, making it a valuable material in modern construction and design. Its wide range of applications, combined with advantages such as durability, lightweight, and ease of maintenance, continue to drive its popularity. As technology advances and environmental considerations become more prominent, ACM will likely evolve further, meeting the demands of innovative architectural and industrial applications.